Identification of plastic packaging with TBS

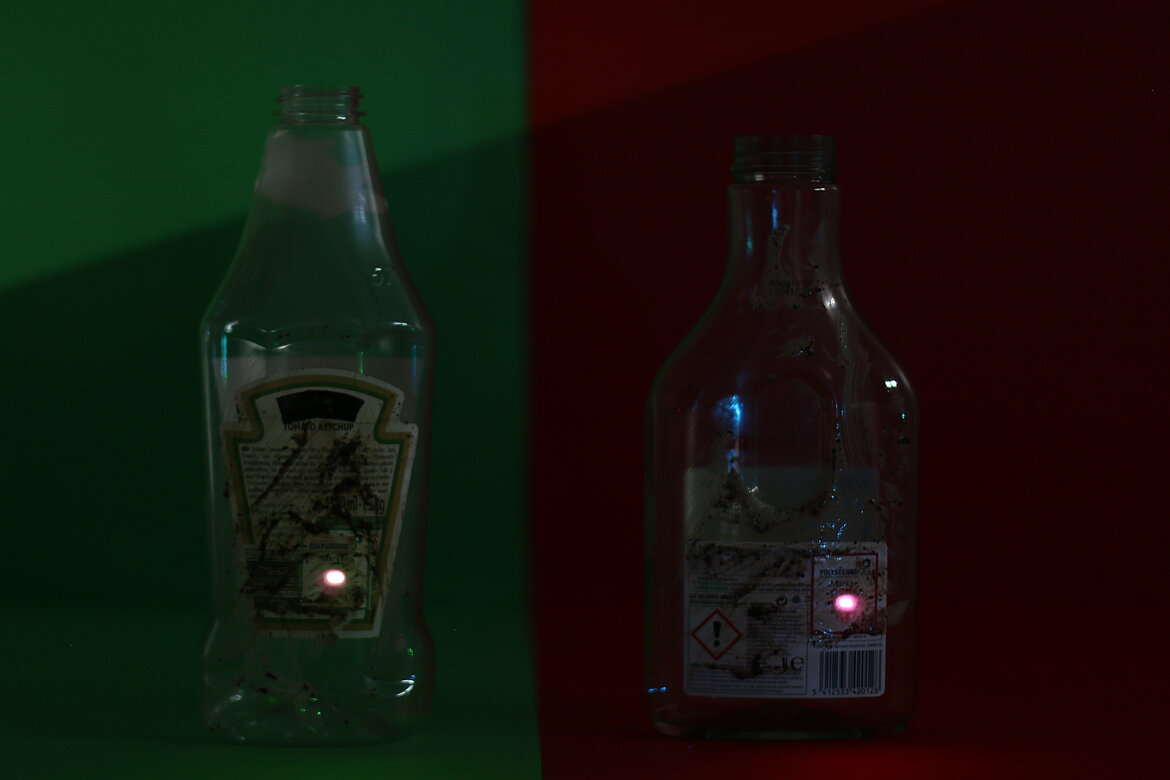

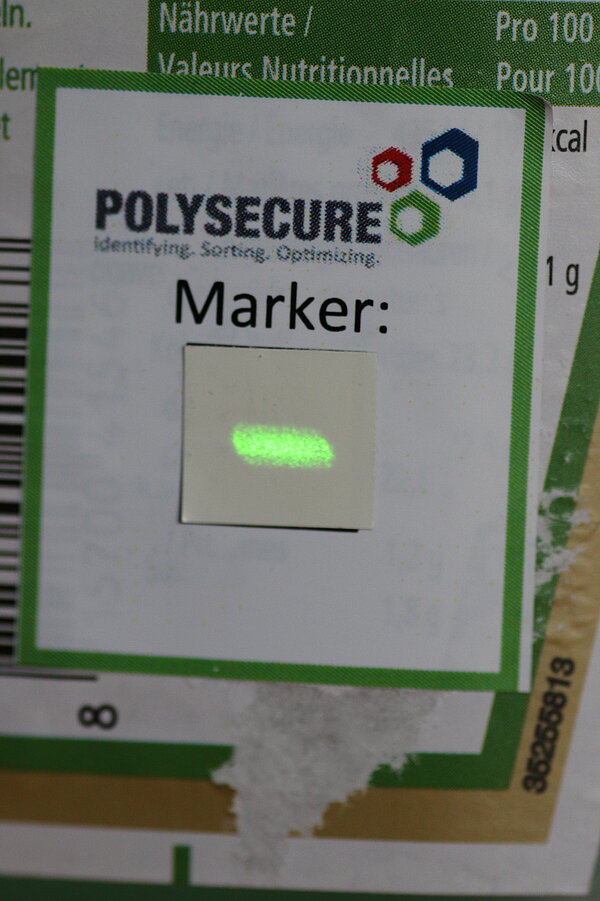

Upon specific excitation, the type of packaging is clearly identified by the fluorescence of the tracer. (Photo: HS Pforzheim / Polysecure GmbH)

Upon specific excitation, the type of packaging is clearly identified by the fluorescence of the tracer. (Photo: HS Pforzheim / Polysecure GmbH)

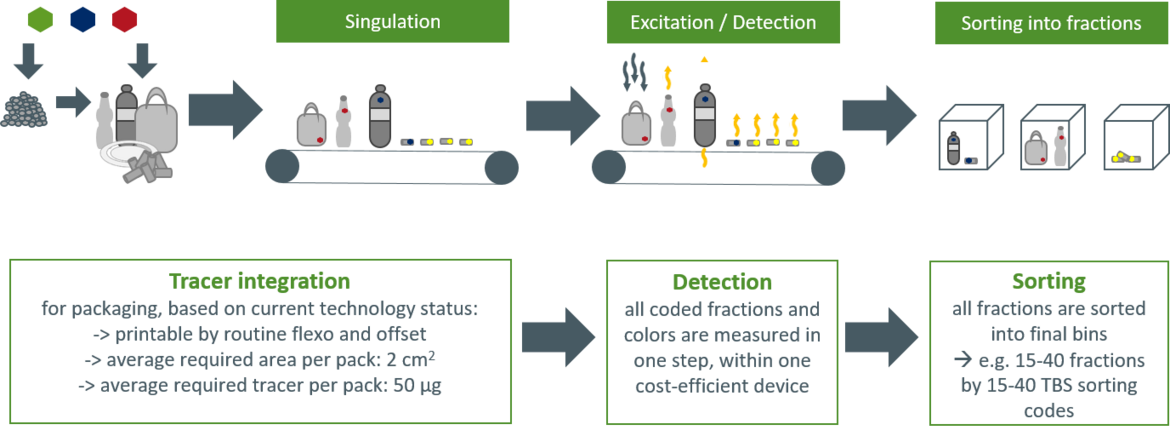

Tracer-Based-Sorting (TBS) uses inorganic tracer substances whose fluorescence is activated when excited with electromagnetic radiation. The fluorescence can be quickly detected and can be used to identify an article or material. Tracer quantities in the ppm range are already sufficient for this purpose. The visible fluorescence requires special excitation sources. Outside of the sorting machines the TBS tracer is completely invisible.

For the identification and sorting of plastic packaging with TBS, packaging is marked with a specific fluorescent tracer according to its preferred (e.g. the most cost-effective) recycling path. This is usually done on the label, which can be separated in the recycling process, so that carryover of the tracer during material recycling is avoided.

If sorting material flows already processed and traded today are re-sorted by a TBS step to increase product purity, this implements the "TBS light" sorting approach. If the TBS sorting replaces conventional sorting steps to a large extent by one TBS sorting step, this can be called "TBS complete". A concrete application example for the further development of existing sorting technology by TBS is the reliable separation of multilayer packaging so that it does not contaminate the mono-material streams.

Further information can be found in our publications - available here.

The approach for packaging identification is using upconversion fluorescence. Inorganic upconversion tracers developed by project partners Polysecure and KIT are excited in the near-infrared (NIR) range and emit in visible light (VIS). This is a unique property of TBS tracer substances that no other natural or synthetically produced material has. Therefore, when detected in the TBS process, only the fluorescence signal of the tracers is present, but no background noise. In the TBS process, the packaging and its constantly changing design does not emit any optical signals that could interfere with the tracer signals. In addition, the fluorescence emission of the tracers occurs in all directions (isotropic). In contrast to other identification techniques such as printing or surface structuring applied to the packaging material, the TBS process therefore does not require any alignment of the packaging relative to the detection unit. It is therefore robust against deformation of packaging and capable of fast and reliable identification even under difficult optical conditions.

The physical efficiency translates directly into low tracer quantities per packaging, numerous easily distinguishable emission spectra or sorting codes, thus resulting in a robust, reliable sorting process that can be used for all packaging types.

The most important option for using the TBS tracers for plastic packaging is to apply them via the printing ink.

The tracers are dispersed in light-colored ink according to the sorting code and then applied to the label or directly to the packaging. On the packaging, the area of one square centimeter (e.g. the white area around the EAN code) is sufficient for identification. After sorting, the tracers are removed from the packaging with the label and the printing ink.

The tracers are highly annealed inorganic crystal particles that are chemically very inert and almost insoluble. Therefore, they behave similar to minerals and thus enable good biocompatibility. The particle size is well over 100 nm and therefore not respirable. One group of materials has already been approved for contact with drinking water as an additive in plastics. Previous laboratory tests have not shown any evidence of toxicological effects of the tracers.