CircoMod

Circular Economy Modelling for Climate Change Mitigation

Decarbonizing the production and consumption of products and materials play a critical role in reaching ambitious climate targets. As a result, a new circular economic system that aims to reduce primary material use (in addition to energy efficiency and fuel shifts) can address both Greenhous Gas emissions (GHG)s and increase resource efficiency. However, current GHG mitigation models and scenarios that inform climate policymakers do not generally include circular economy (CE) options. They also do not cover the possible synergies of the CE with other societal goals such as the Sustainable Development Goals (SDGs), nor the challenges involved in rearranging value chains and consumer behaviour.

CIRCOMOD addresses these challenges by developing a new generation of advanced models and scenarios that will assess how CE can reduce future GHGs and material use. The project brings together a unique consortium of leading research teams from different disciplines, including industrial ecology and material flow modelling, process-oriented integrated assessment modelling, and macro-economic modelling. It aims for a breakthrough in integrating CE and GHG mitigation assessments by developing an analytical framework that maps circular economy strategies to existing influential climate scenarios; by providing robust and timely CE data in an open repository; and, by improving the representation of the CE in leading models used by European and global institutions, while strengthening links between the models.

These key scientific breakthroughs enable robust scientific assessments in collaboration with stakeholders across policy and industry. It will provide timely input to international assessments such as the Intergovernmental Panel on Climate Change (IPCC) and the International Resource Panel (IRP). CIRCOMOD will provide actionable insights into the circular economy and help address one of the largest challenges of the coming decades.

Universiteit Utrecht (UU), Coordination

Norges Teknisk-Naturvitenskapelige Universitet, Trondheim (NTNU)

Universiteit Leiden (CML)

Albert-Ludwigs-Universität Freiburg

Fondazione Centro Euro-Mediterraneosui Cambiamenti Climatici, Lecce (CMCC)

E3-Modelling AE, Athens (E3M)

Stichting Katholieke Universiteit Brabant, Tilburg (TiU)

Universidade Nova de Lisboa

Systemiq Deutschland GmbH, Munich

Power Algae OU, Tartu

Ministerie van Infrastructuut en Waterstaat, Den Haag (PBL)

DACE

Data Competence Center for Circular Economy

The circular economy depends to a large extent on information about the manufacture, production and use of products, their materials and their components. However, due to the complexity of many products and the underlying production processes, the collection, consolidation and evaluation of this data - the circular economy (CE data) - is extremely difficult and requires a great deal of knowledge and analysis. The underlying CE data must inevitably be collected by different institutions due to the wide variety of processes and actors involved, whereby a large amount of necessary CE data is not yet collected today. There are various reasons for this. Firstly, because they are not yet recordable or measurable. Secondly, because it is not yet known that this data is needed at all in the context of CE. This also means that many areas of CE cannot or can hardly be mapped reliably in terms of data and information technology at present. The actual progress of CE development, e.g. through the impact of policy measures, can therefore only be tracked to a limited extent or not at all. Therefore, CE data requires both the development of expertise and further research in order for it to be useful. To this end, the ability to collect, analyze and derive measures from CE data must be developed, expanded and strengthened among various target groups, but especially in the scientific community. This is precisely where the Data Competence Center for Circular Economy Data (DACE) comes in.

The DACE - Data Competence Center for Circular Economy (CE) Data

- researches the skills required to collect, analyze and use CE data,

- enables the handling of CE data,

- and networks the players in data-driven CE.

The aim is to enable research into and implementation of the energy- and resource-efficient circular economy. At the same time, the basis for better measurement and evaluation of CE and CE strategies (10R) is to be created through the systematic handling (skills) of CE data in science, research, teaching and application. DACE will thus close an important gap in the research and learning landscape for sustainable management.

Central competencies must be imparted in particular in the identification and recognition of the need for required and relevant CE data, its collection and recording, its provision across different stakeholders, the consolidation and consolidation of the data and its holistic analysis. DACE relies on three main pillars in order to teach the required skills:

- the DACE Academy to teach the skills,

- the DACE Space to research the skills and

- the DACE Hub to disseminate the skills.

The project is organized into work packages. Work package (WP) 1 deals with the coordination of the Data Competence Center. In WP 2, the DACE Academy is conceptualized, set up, implemented and evaluated. The INEC has a major contribution here in the transfer of knowledge and skills. In particular, appropriate formats will be developed, for which a target group analysis will first be carried out. Stakeholder surveys are also carried out to analyze the target group in order to design formats and curricula. The entire knowledge transfer process will be scientifically monitored. WP 3, the DACE Space, is another focus of INEC's work in the DACE project. INEC has extensive project experience in the use and conceptual creation of data for the circular economy. INEC complements the DACE research with activities on the importance of data in resource efficiency, in data literacy for CE and on issues of standardization and standardization for CE data and its handling. This relates in particular to work on data collection, provision and analysis. As part of this work package, concepts for indicators, databases and data management will also be developed together with the partners. Proposals will be developed and discussed before they are tested in practice in order to ultimately implement data-driven CE measures. Finally, as part of WP 4, the DACE Hub will be set up as a networking platform to bring together the relevant players in a data-driven circular economy.

Wuppertal Institut für Klima, Umwelt, Energie gGmbH (Coordinator)

University of Wuppertal (BUW), Institute for Technologies and Management for Digital Transformation

German Research Center for Artificial Intelligence (DFKI), Department Innovative Factory Systems

RWTH Aachen University, Chair of Anthropogenic Material Cycles and Center for Circular Economy

DfC Industry

Design for Circularity in industrial product development

The development of circular and resource-efficient products is an important instrument for contributing towards sustainable development. This requires product development and design processes to automatically evaluate circular economy measures such as lifetime extension, reuse, remanufacturing or high-quality recycling with regard to economic efficiency, sustainability and resource efficiency.

DfC-Industry aims at developing and testing digital solutions for the design of circular, energy- and resource-efficient products. This includes the environmental assessment of material and energy flows in early design stages as well as the economic feasibility and business models of potential solutions. The analysis of current product development processes helps to derive rules and frameworks for a design for circularity. Furthermore, artificial intelligence and further IT-based approaches are explored to enable and automate the application of these solutions and thereby operationalize a Design for Circularity (DfC) in industrial settings.

The project is coordinated by Pforzheim University’s Institute for Industrial Ecology. The design and product development processes of the project partner Robert Bosch GmbH serve as test cases, while the two further partners, ifu Hamburg GmbH and the Smart Enterprise Engineering unit at Deutsches Forschungszentrum für Künstliche Intelligenz GmbH (DFKI-SEE), contribute their specific IT knowledge and expertise.

Robert Bosch GmbH (BOSCH)

iPoint-systems gmbh und ihr Tochterunternehmen ifu Hamburg (IFU)

The project is funded by the Federal Ministry for Economic Affairs and Climate Action as part of the funding program „Ressourceneffizienz im Kontext der Energiewende“ (resource efficiency in the energy transition context), which is administered and coordinated by Project Management Jülich (PtJ).

https://www.energiesystem-forschung.de/forschen/ressourceneffizienz

greenProd

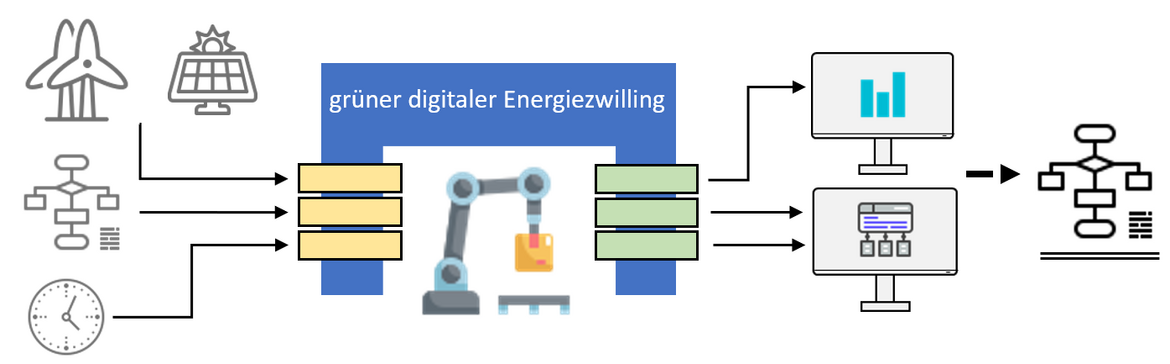

Energy optimized production with green digital twins

Large parts of the manufacturing industry are facing major challenges in view of the energy transition. The increased use of regenerative energy as well as the efficient use of available energy are associated with high investments.

The aim of the greenProd research project is to optimize the transformation of the manufacturing industry with regard to the use of regenerative energy sources and at the same time to increase its competitiveness.

In order to achieve this, it is first necessary to determine the energy requirements of the individual production steps. Energy efficiency potential can then be identified and concepts for the optimized use of renewable energy can be developed. This is to be done with the help of green digital energy twins (gDEZ). These are digital proxies that describe the energy consumption of production steps and can also be supplemented with emission data. The gDEZs thus enable the CO2 emissions to be allocated to the production steps and the individual products.

With the aid of the digital image of a production system, interdependencies between machines and systems can be represented and entire production chains can be simulated. By specifically shifting energy-intensive work steps to times when sufficient regenerative energy is available, production can be optimized in terms of costs and environmental impact.

In summary, the scientific and technical challenges of the project are:

- Description of the energy consumption of individual production steps by means of gDEZ

- Simplified creation of the gDEZ and the configuration of processes

- Development of an algorithm for energy-optimized production planning

- Integration into existing processes and plants

- Visualization of the advantages in business figures

H2Chemie2050

Without detours to green hydrogen in chemical-pharmaceutical production by 2050

Hydrogen is the starting point and component of numerous industrial value chains. In order to achieve the climate protection goals of the EU, the federal government and the state of Baden-Württemberg, a climate-friendly industry is needed by 2050 and thus also a hydrogen economy with low greenhouse gas emissions. The necessary conversion to hydrogen-focused, greenhouse gas-neutral value chains offers diverse challenges and, in particular, opportunities in the areas of production, distribution, storage, application and products.

The aim of the H2Chemie2050 research project is to actively support the transformation of industrial production in the chemical-pharmaceutical industry and to close the gap from "grey" to "green" hydrogen. Together with the project partner Evonik Operations GmbH, INEC will create a practical action and decision support system that can be transferred to all relevant industrial locations for the optimal design of the transformation process from "grey" to "green" in the area of the industrial use of hydrogen.

Furthermore, the aim is to select the optimal and most efficient sequence and combination of technologies and processes that will ensure the fastest possible transformation. Technology paths are evaluated by means of techno-economic and life cycle assessment system analyses in order to avoid ecological as well as economic detours, wrong turns and dead ends and thus time delays and unnecessary costs.

InPEQt

Integrated cost- and life-cycle-based planning of decentralized energy systems for energy and resource efficient neighborhood development

In renewable energy systems, the environmental impacts shift from the use phase to the production phase on the one hand, and also to other impact categories on the other. Therefore, a fundamental extension of the methodology for energy system planning is required. The coupling of classical energy system modeling with life cycle assessment offers the opportunity to do so.

The main objective of this project is to develop and test a planning model for decentralized energy systems at the neighborhood level, which enables a comprehensive environmental impact assessment and integration with technical and economic aspects. The planning model to be developed supports the transformation to climate-neutral energy supply systems for neighborhoods while minimizing other environmental impacts. Conflicts between environmental impacts and costs as well as between the environmental impacts themselves are resolved or minimized. The results of the model are expansion and deployment paths for energy supply technologies over time with balanced and overall reduced environmental impacts in the individual impact categories. The results obtained are to serve as a basis for setting the course in neighborhoods by deriving concrete specifications, e.g. for development plans, for new neighborhoods. In existing neighborhoods, the results will be used in particular to identify and define suitable incentives to support the environmentally friendly transformation of energy systems. To ensure the practicality of the planning methodology, the developed model will be applied to three different practical cases and successively adapted. In Gerstetten, Constance and Wiernsheim, a total of two new-build and one existing neighborhood will be studied to consider and test the different requirements.

IRMa

Integrative resource efficiency management for small and medium-sized enterprises in the chemical industry

In the research project "IRMa", case study-based research is to be carried out on how an Integrated Resource Efficiency Management (IRMa) can be designed and implemented for small and medium-sized enterprises in the chemical industry. The results will be processed in a transfer-oriented manner and generalised with the help of a project advisory board and carried into the breadth of the industry. The aim of the project is to ensure the systematic development of the circular economy potential in SMEs in the process industry and the associated energy efficiency potential with a consistent methodological approach for SMEs in the chemical industry, to validate it as a model and to process it in a transfer-oriented manner. In the IRMa project, decarbonisation and circular economy strategies as well as the associated measures are thus developed in order to achieve international and national climate protection and sustainability goals for SMEs in the chemical industry.

The procedure for achieving these goals includes...

- the analysis and evaluation of the company and its internal processes and products with regard to the challenges posed by the circular economy, energy transition and environmental and climate protection,

- deriving and evaluating internal and external options for action and improvement measures for closing the loop, as well as validating and evaluating selected technologies for closing the loop and energy efficiency, and

- the structuring of interfaces for inter-company networking and implementation of circular and energy management approaches as well as the validation of their effectiveness.

KliReGeM

Climate-resilient building management

The predicted increase in extreme weather events due to climate change, including long periods of summer heat, create special challenges for building management and urban planning in many cities and municipalities. To minimize the impacts of climate change, there is a portfolio of diverse climate adaptation measures in the urban environment.

In the project "Climate-Resilient Building Management" (KliReGeM), action guidelines for climate-adapted and resource-saving building management are being developed based on the life cycle assessment of concrete climate adaptation measures in the context of typical urban construction tasks in the field of non-residential buildings (new construction, renovation, repair).

The aim of the project is to develop best practice examples for climate-sensitive construction and building management that can serve as models for other cities and municipalities and, beyond that, for commercial non-residential buildings such as offices.

The project has the following sub-objectives:

- development of a system of climate adaptation scenarios

- comprehensive assessment of environmental impacts for the different scenarios

- development of action guidelines for climate-resilient construction

For this purpose, the Institute for Industrial Ecology of the Pforzheim University of Applied Sciences and the Department of Structural Engineering and Building Management of the City of Karlsruhe are working together in close exchange with the involvement of other stakeholders.

Kreislauf E-Wende

Closed-loop energy transition: Balancing the reduction of greenhouse gases through future material cycles in the life cycle of energy technology systems and components

The energy transition is associated with increased material requirements. It is therefore essential to reduce the greenhouse gas emissions associated with materials and to reduce possible supply risks from critical raw materials. Measures of the circular economy are expected to make a significant contribution to this.

The methodology of life cycle assessment is widely used to evaluate greenhouse gas emissions. However, the consideration of material cycles is a major weakness in the available accounting tools. On the one hand, this is due to the uncertainties about the possibilities of the Circular Economy that will come into play in the future and the need to include the temporal dynamics of the future energy transition itself in the accounting. On the other hand, fundamental methodological and data-related problems of life cycle assessment come into play when accounting for material cycles, for example the allocation of greenhouse gas savings from recycling.

In this context, both companies and energy and resource policy are currently facing the following challenges:

- The measures triggered by the EU Green Deal demand more detailed reporting on greenhouse gas emissions from industry, taking materials into account; the Taxonomy Regulation will also lead to a need for action on the part of companies.

- The rapid transformation of the energy system also relies on the replacement of older, less efficient plants. This requires break-even point calculations for the renewal or replacement of plants.

In principle, the results of today's balancing of an energy technology can have a significant influence on its marketability and dissemination for the future. Therefore, the anticipation of future developments in the sense of an ex-ante consideration is essential for a reliable decision support.

Based on these challenges, the consortium of science and industry will work on the following research topics:

- Methodological issues of life cycle assessment of greenhouse gas emissions of materials in future material cycles

- Analysis of the implementation of components and plants in the energy system against the background of the transformation to renewable energies

- Development of scenarios of future recycling technologies and analysis of the resulting substitution potentials

The overall project goal is thus to develop methods and data sets for the greenhouse gas balancing of energy technology plants and components that take into account the future effects of Circular Economy measures.

TU Darmstadt, Institut IWAR, FG Stoffstrommanagement und Ressourcenwirtschaft (Coordinator)

Forschungsstelle für Energiewirtschaft e.V.

Siemens Energy Global GmbH & Co. KG

MEiK

Single-use medical devices in the circular economy

The current status of waste disposal from the healthcare sector in Germany shows that the existing regulations and solutions only take hygiene and occupational safety aspects and economic efficiency into account, but practically ignore climate and environmental sustainability requirements. Around 5% of German greenhouse gas emissions are attributable to the healthcare sector, while the global share is around 4.6%. In absolute terms, the per capita emissions of this sector in Germany, at over 800 kg CO2e, are around a third higher than those of other EU countries, which emit around 600 kg CO2e per inhabitant per year.

The aim of the project is to develop a largely carbon-neutral, high-quality material recycling process for single-use medical products with a high plastic content in Germany, to demonstrate it in practice and to evaluate it from an environmental and economic perspective. The demonstration will be based on selected medical products from the project partners and will serve as the basis for a comprehensive recycling solution for the entire waste stream. Selected products are to be examined over their entire value creation cycles and optimized across all partners, from product design to high-quality material recycling. The results will be processed and presented in a way that is transferable to other medical products, and these findings will be fed into the public discourse, including standardization bodies, in a targeted manner. The product design, the targeted minimization of waste generation and material recycling as an alternative to energy recovery or disposal can achieve significant positive climate effects of around 560,000 t CO2e/a.

PFAS

Application, technical functions and substitution possibilities in the industry

Per- and polyfluoroalkyl substances (PFAS) are organic compounds consisting of carbon chains in which the hydrogen atoms are completely or partially replaced by fluorine atoms. The strong chemical bonds between carbon and fluorine atoms in PFAS lead to very stable substances with particularly useful properties such as chemical inertness, water repellency, lubricity, non-stick properties, fire resistance and heat resistance. However, they are not easily biodegradable and are therefore difficult to decompose in the environment (Ye et al. 2015).

PFAS are used in many fields of application in industry and in end products, such as in industrial production, in seals, lubricants, packaging, metal coatings, in medical technology products, electronic devices, solar cells, fuel cells, batteries, in the construction sector and also in consumer products in textiles, cookware and cosmetics (Glüge et al. 2020, ECHA 2023). Due to their effects on the environment and humans and their persistence in the environment, PFAS are currently the subject of much debate and an initiative has been launched at EU level to potentially ban substances (ECHA 2023). Companies from Baden-Württemberg and all over Europe are now looking for substitutes for the use of PFAS in order to have alternatives available in the event of a possible substance ban.

The aim of this meta-study is to create an overview of possible substances and substance groups that have the potential to replace the technical functions of PFAS. This will be examined in depth using selected examples.

The focus is on the following questions:

- Where are PFAS used/applied so far? What technical functions do PFAS provide?

- Which other substances could be substituted for PFAS?

- What conclusions can be drawn from this for the development of innovation in industry in Germany and Baden-Württemberg in particular?

Using software tools based on artificial intelligence (AI), possible substitutes are identified and evaluated in a structured manner. First, the status quo of the use of PFAS in industrial applications is examined, with particular attention being paid to the companies involved and the applications in which PFAS currently still play a significant role. The empirical identification of alternative materials through AI-supported research is then described. An extensive data pool of material research publications is used as a basis and a specially developed AI system is used to extract relevant information. Finally, the identified materials are evaluated for their suitability as potential substitutes for PFAS in industrial applications.

präziSort

Development and construction of a pilot plant with integral detection for precise individual sorting of plastic waste

The aim of the project is to develop and construct a pilot plant based on Polysecure's new sorting process, which can significantly increase the low recycling rate for plastics in particular.

The implementation of three central innovations is planned:

-

the plant engineering realization of single line sorting with continuous object separation, combined detection and targeted depositing of the separated objects. This means that all objects are identified and sorted in just one step, making the sorting process flexible, scalable and economical, even with numerous fractions, in contrast to the established multi-stage sorting process.

-

the development of a new integral detector that simultaneously measures and evaluates tracer, NIR, color and image for each object. This enables reliable sorting into definable, unmixed fractions, from which significantly more high-quality recyclates can be produced, particularly through CO2-efficient mechanical recycling.

-

The development to industrial maturity of the tracer-based sorting (TBS) process patented by Polysecure within a complete industry-typical pilot plant. TBS is based on the use of fluorescent additives (tracers), which - unlike existing sorting processes - enable reliable identification independent of the object.

Pforzheim University is conducting the accompanying research for the system development of the project partner Polysecure. The focus is on the following research objectives:

-

Provision of economic, technical and ecological material, planning and market data for the recycling of the object streams that are the focus of the project and

-

Optimization and evaluation of the pilot sorting plant via sorting tests, integration of stakeholders and their requirements as well as consideration of material, planning and market data.

Specifically, a comprehensive collection and sorting study on the quality and quantity of lightweight packaging is being designed and carried out with the aim of characterizing at least 250 kg of lightweight packaging in depth and thus providing basic design data for the further technical and economic development of the TBS process. This further development at the project partner Polysecure is accompanied by technical and scientific support and serves the research application of innovation methods in the process development and market launch of the process. Another research focus is the collection of environmentally relevant process data and the preparation of a life cycle assessment for the process to accompany development.

PRESERVE

Circular economy for key materials in electromobility and renewable energy - Concepts for the evaluation and use of recycled materials from rare earth magnets and Li-ion batteries

Concepts and tools are being developed for the circular economy of magnets and batteries and linked to LCA considerations. The aim is to evaluate recyclates of rare earth magnets and Li-ion batteries efficiently and in a standardized way, to predict their aging properties and to derive use limits and suitable applications.

For this purpose, the influence of the recyclate properties on the application properties of the components and their aging will be comprehensively investigated. Material composition, microstructure and any defects that occur must be carefully analyzed to minimize the risk of increased aging.

By incorporating artificial intelligence methods, user-friendly and industrially applicable software tools for efficient quality assessment and property prediction are created. This conserves critical resources, increases sustainability and lifetime of e-machines and batteries, and makes supply chains less dependent on the Asian market.

Prof. Dr. Carlo Burkhardt

Hochschule Aalen (Project coordination)

RewitAl

Re-integration of highly weathered used plastics into the circular economy

The interdisciplinary approach in RewitAl under participation of industry and civil society organisations pursues the circularity of materials and the activation of recycling in the plastics industry. The focus is on the hitherto rather neglected but quantitatively significant highly weather-stressed plastics on the example of sports facilities with plastic surfacing systems.

The focus is on (i) the environmentally friendly dismantling of the system, taking into account the microplastic spread into the environment, (ii) the analysis of the optimal suitability of various recycling processes for the different weather-stressed plastics of the system, and (iii) the investigation of possible alternatives on the basis of bio- and recycled plastics.

The comparative economic and ecological evaluation of materials and processes, combined with a comprehensive description of properties, is the key factor for transfer to sustainable application scenarios and business models.

Hochschule Aalen (Project coordination)

ZIRU

Industrial application of circular and resource-saving product development processes

The transformation of the current economic system towards a circular economy is a core strategy for climate protection and resource conservation in European by national and Baden-Württemberg policy. Such a transformation presents companies with major challenges and requires new business models and circular products and services.

The ZIRU research and transfer project aims to systematically anchor resource conservation and the circular economy in the industrial product development processes of companies in Baden-Württemberg. The project analyses and improves the product development processes and selected products and product groups of the associated industrial partners with regard to circularity. ZIRU involves companies from the manufacturing industry in order to enable the methods and principles to be disseminated beyond the project.

The creation of self-explanatory workshop and training documents for potential multipliers in the field (e.g. chambers of industry and commerce, consultants) is also an objective of the project, as well as the further development of the web-based tool "Circularity Navigator", which enables its users to select circular business models, design principles, measures and indicators that are suitable for them.

Completed projects can be found in the project archive.