Results

Packaging Design & Tracer Development

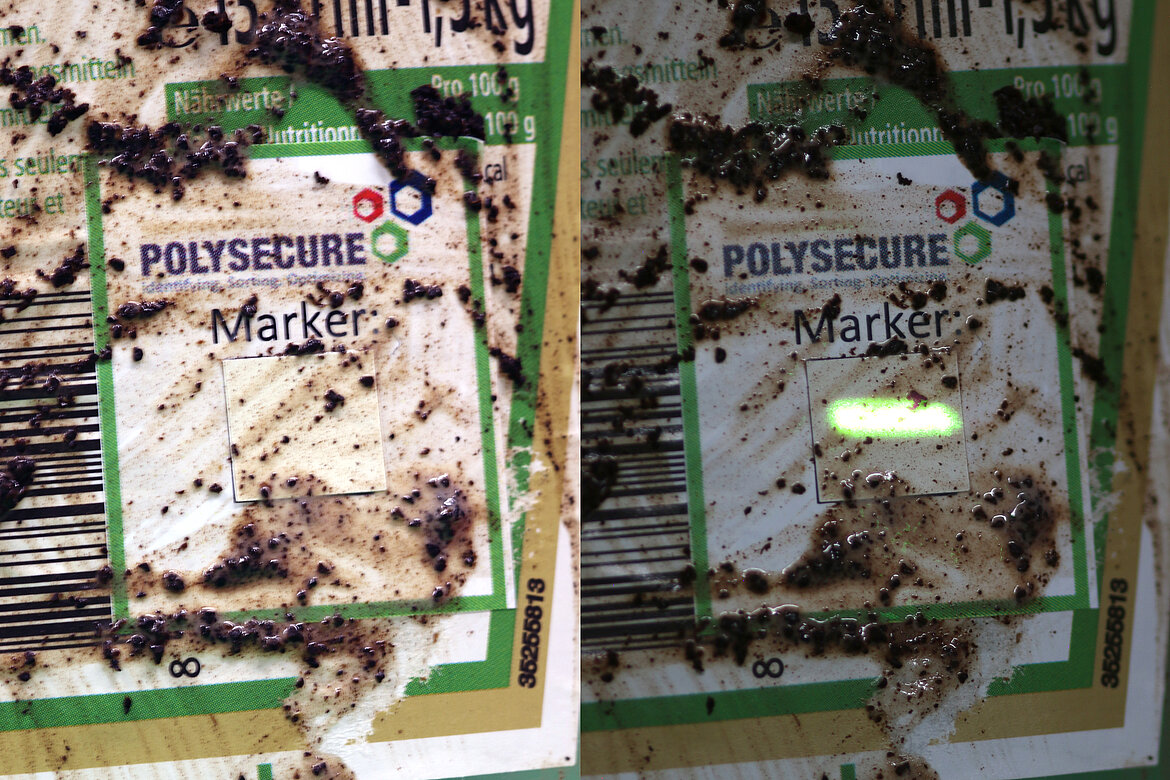

As part of the MaReK project, new efficient, inorganic, biocompatible upconversion fluorescence tracers were developed. Furthermore, it was experimentally verified that small amounts of the tracer are sufficient for a fast and reliable detection. The tracer technology works for all types of packaging, including soiled, crushed, deformed or black packaging. Studies on tracer integration in practice show that the application of the tracer in light-colored ink on the label of the packaging is the most promising option. In this way, the tracer is simply removed with the label and/or the printing ink in the recycling processes. The establishment of an efficient synthesis and post-treatment process for the production of tracers is another milestone.

Recycling-oriented characterization of lightweight packaging

While previous studies on packaging characterization mostly only covered parameters relevant to waste management, such as the packaging materials and to some extent the geometries of the packaging materials (bottles, cups, etc.), this study was the first to provide a comprehensive packaging characterization of light packaging waste. For this purpose, not only the geometries or packaging materials, but also those of the closure systems were recorded, and in addition, among other things, colors, label types and materials, as well as filling goods and their storage requirements were documented. In the case of multilayer packaging, the number and materials of the layers were examined in detail, the degree of contamination was recorded, and all packaging examined was photographed. Thus, a comprehensive data and photo collection of the contents of a total of 248 “science bags” is available. The photo documentation can serve as a basis for the development of AI sorting approaches. The consolidation and evaluation of the tabulated data has already been started. They will provide the detailed information on the properties of light packaging waste needed for the MaReK project to determine throughput rates and to calculate profitability.

A total of almost five hundred households participated in the Germany-wide study. The households collected their lightweight packaging in a "science bag" for two weeks each, which they sent back to Pforzheim University as a return shipment. In total, the study was based on 248 science bags with a total volume of about 24 m³ and typically about one hundred individual parts per science bag. The total mass of the packaging characterized by the study was 257 kg. A total of 27,000 individual parts were identified, characterized and photographed. The work was carried out between October 2019 and July 2020 in cooperation with another project funded by the BMBF/"Plastics in the Environment" (Verbraucherreaktionen bei Plastik und dessen Vermeidungsmöglichkeiten am Point of Sale - VerPlaPoS). This project is managed by the city of Straubing. The Weihenstephan-Triesdorf University of Applied Sciences as a cooperation partner of VerPlaPoS has collected the socio-economic background information of the study participants in the course of the scientific bag cooperation.

TBS sorting trials

Sorting trials with packaging samples are carried out. The functionality of the technology under challenging conditions (especially dirty, deformed, black packaging) is tested. For the identification of the marked articles a cost-effective and fast detection unit was developed. The conveyance of typical packaging articles from the detection unit was successfully demonstrated with a split tray sorter.

Prof. Dr.-Ing. Jörg Woidasky discusses with participants of the stakeholder workshop. (Photo: HS Pforzheim)

Prof. Dr.-Ing. Jörg Woidasky discusses with participants of the stakeholder workshop. (Photo: HS Pforzheim)

Since Tracer-Based-Sorting is a fairly complex innovation that will have a significant impact across value chains, it is important to involve the stakeholders at an early stage of the innovation. Within the MaReK project, two stakeholder workshops were successfully carried out, including an international workshop in September 2019 to present the results achieved so far and to showcase the TBS technology by means of a demonstrator sorting system. The workshop participants represented the areas of packaging production, consumer brands, retail and waste management as well as public administration, thus providing an excellent forum to discuss not only technical but also organizational and political issues regarding implementation. Around 40 international representatives from industrial companies, major brands, research institutes and waste management authorities accepted the invitation. In addition to the demonstration of the "Tracer-Based-Sorting" (TBS) technology, other aspects, such as the manufacturing processes of the tracers or the possibilities of integrating the tracer on and in the packaging, were discussed. The subject of other working groups was the further industrial implementation of TBS. Important results were, besides the applicability of TBS technology for the separation of food and non-food packaging, the identification of non-recyclable composite packaging or the further separation of individual polymer types.

Several important brands, packaging manufacturers and waste management companies are specifically interested in the technology and are working with project partner Polysecure to optimize and implement the TBS process for specific issues. Large technology companies are also specifically interested in implementing the TBS technology globally as strategic investors within an industrial consortium. Especially countries that have established little or no sorting and recycling technology can skip the (German) state of the art ("leap frogging") with the TBS process and achieve a high recycling rate and high profitability.

Potential environmental impact

Within the project, a life cycle assessment of the sorting and recycling processes of lightweight plastic packaging was carried out. In a first step, the current status of modern, conventional sorting plants was mapped in a life cycle assessment software and is thus available for the investigation and ecological evaluation of the sorting technology. As a second step, the use of Tracer-Based-Sorting (TBS) was modelled in two scenarios ("TBS light" and "TBS complete") in addition to conventional sorting technology. The modelling of the conventional sorting and recycling system in Germany and the design of the scenarios with TBS are based on a comprehensive literature analysis and supporting expert interviews. The modelling of the systems and their life cycle inventory in the software Umberto LCA+ and the subsequent evaluation of the impact assessment show the ecologically beneficial effects of TBS. From an environmental point of view, material recycling is generally advantageous compared to the use of primary plastics. Furthermore, "TBS light" can achieve a slight increase in total savings of greenhouse gas emissions compared to the conventional system of packaging recycling. "TBS complete" even shows the potential of a significantly higher total saving. It corresponds to a saving of greenhouse gas emissions of more than twice the amount compared to the conventional packaging recycling system. The effort of implementation in the existing system is offset by an improved sorting quality and the possible differentiation of material-specific packaging categories, which allows the increased use of recycled material, for example in the food sector.

Both approaches with TBS are more environmentally friendly than the existing packaging recycling system. They meet the requirements of a sustainable recycling economy through high-quality recycled material and thus also enable a higher rate of use of recycled material. The substitution of virgin plastic by recycled material results in savings of approx. 2.5 kg CO2 equivalents per kg of plastic for the main polymers [Dehoust and Christiani 2012; Kauertz et al. 2018].

References:

- Dehoust, Günter; Christiani, Joachim (2012): Analyse und Fortentwicklung der Verwertungsquoten für Wertstoffe. Sammel- und Verwertungsquoten für Verpackungen und stoffgleiche Nichtverpackungen als Lenkungsinstrument zur Ressourcenschonung. Hg. v. Umweltbundesamt. Dessau-Roßlau.

- Kauertz, Benedikt; Bick, Carola; Schlecht, Samuel; Busch, Mirjam; Markwardt, Stefanie; Wellenreuther, Frank (2018): FKN Ökobilanz 2018. Ökobilanzieller Vergleich von Getränkeverbundkartons mit PET-Einweg und Glas-Mehrwegflaschen in den Getränkesegmenten Saft/ Nektar, H-Milch und Frischmilch. Hg. v. ifeu - Institut für Ener-gie- und Umweltforschung Heidelberg GmbH. Heidelberg.

- Kusch (2020) Ökobilanzielle Bewertung der Sortierung und Verwertung von Leichtverpackungen aus Kunststoff mit Betrachtung der Optionen durch TBS. Masterthesis at Pforzheim University of Applied Sciences.